Warehouse Storage Predictor

Data Modeling • 2025 • Internship Project

Overview

An interactive dashboard that helps warehouse managers choose the best storage solution based on SKU frequency, slotting patterns, and time-of-day usage.

Role: Data Modeler & Developer

Tools: Figma, Python (pandas), Tableau, Excel, Google Colab, Google Slides

Problem

Warehouse managers often rely on gut feeling or overly simple rules to make complex storage decisions. With rising costs and growing SKU complexity, there’s increasing pressure to reduce pick times, maximize space, and justify automation investment. But existing dashboards are often cluttered, generic, or built by engineers without UX training—leading to analysis paralysis and costly inefficiencies.

My Approach

- User Research: Used available data to understand workflows and data pain points

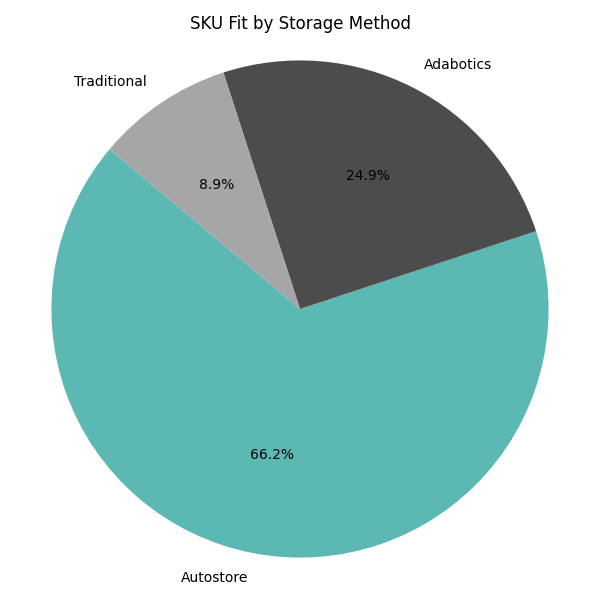

- Data Modeling: Built a Python-based predictor that scores SKUs by frequency and maps them to ideal storage types (AutoStore, Adabotics, traditional shelving)

- Wireframing: Sketched dashboards that balanced logic depth with visual clarity

- Prototyping: Used Figma and Tableau to design and test interactive layouts and filter controls

- Iteration: Gathered feedback from supply chain students and mentors to refine terminology and labeling for non-technical users

Prediction Logic

- Built a scoring algorithm to evaluate SKUs based on order frequency, time-of-day activity, and slotting history

- Defined logic trees for selecting ideal storage systems (AutoStore, Adabotics, or traditional shelving)

- Included adjustable thresholds to test what-if scenarios (e.g. changes in pick volume or peak hours)

- Emphasized explainability of model output for non-technical stakeholders

Final Build

Predictive scoring algorithm built in Python and tested using mock SKU datasets. Tableau used to build initial interactive prototype for dashboard visualization.

Reflection

This project helped me realize how critical interface clarity is for high-stakes operational tools. I’m proud of making something technical feel approachable to both analysts and floor managers. Next time, I’d involve more direct user testing within actual warehouse settings—but for now, this was a strong example of cross-functional UX applied to real-world logistics.